Components vs. Modules: Pros and Cons

- Share

- Issue Time

- May 18,2023

Summary

The thermal imaging market is particularly innovative. Here we compare components and modules, giving you the main technical differences so you can understand the pros and cons of each.

Small and medium-sized manufacturing companies face special challenges when it comes to product line innovation and diversification. However, this is exactly what these companies must do in order to remain competitive.

The thermal imaging market is particularly innovative. Change is constant, and so is growth. The market has been expanding rapidly for several years.

Today, small and mid-sized manufacturing companies looking for new growth drivers - particularly system builders - are turning to thermal imaging to enhance their new products.

Integrating infrared capabilities into existing systems or developing new systems that take advantage of this technology can be an effective way to boost sales.

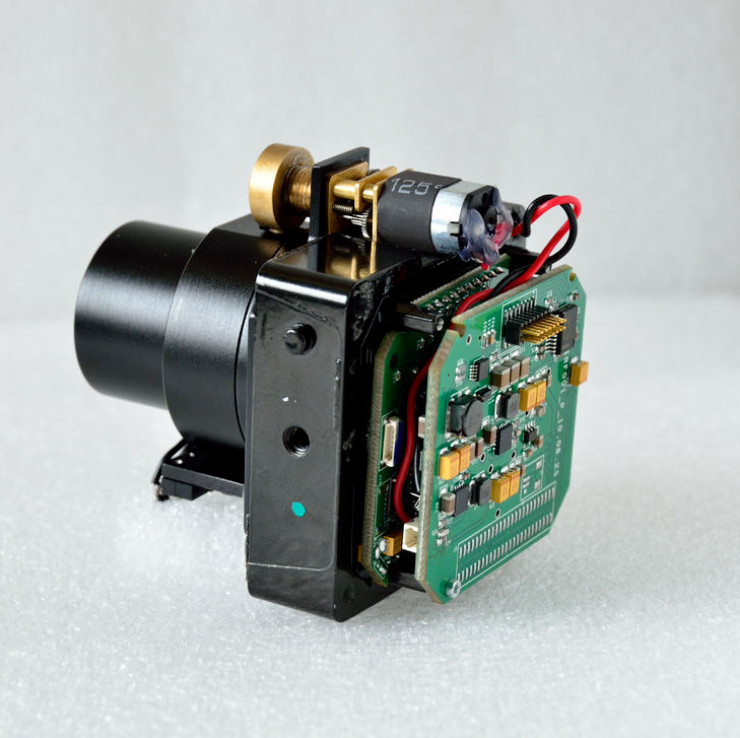

In practice, however, the first question a manufacturer must answer when developing a new product with integrated thermal imaging is whether to choose a ready-to-use module or a thermal camera.

Here we compare components and modules, providing you with key technical differences so you can understand the pros and cons of each and choose the best solution for your development strategy.

Advantage

- Ease of Integration: The modules are fast and easy to integrate as they are pre-built and require no calibration or electronics. Modules are a plug-and-play solution that provides the system with a correct usable image out of the box. In terms of manufacturing, modules are easier to integrate into the production process than components.

- Compatible with small batch production: the module does not require specific manufacturing equipment and is suitable for small batch production. Modules are a particularly attractive solution for companies without in-house camera calibration equipment or expertise.

- Reduced product development costs: Manufacturing products using modules helps manufacturers save development costs compared to developing products that integrate individual components. Developing the custom electronics and calibration algorithms required for the components requires significant investment. The return on investment is only attractive for medium to large production runs.

- Shorter development cycles: Developing a camera from a module takes significantly less time than developing a camera from individual components, resulting in faster time to market.

Shortcoming

- A limited number of configurations: Modules are prefabricated components that cannot be taken apart or modified. Therefore, the number of possible product configurations is limited. For example, parameters such as image format cannot be changed. The number of optical configurations is also usually limited. The number of fields of view is usually limited to about six to eight configurations.

Components

Advantage

- Versatility: Starting with the imager, product designers and developers can adapt the thermal imager to the needs of the target application. Manufacturers can choose the optics they want and tailor parameters such as sensitivity and image frequency to the needs of the end product.

- Freedom of design and development: Modules are designed and packaged for specific purposes. Components offer more possibilities in terms of product design and can be configured to provide the best performance for the target application.

- Cost control: Starting from the sensor, manufacturers can control the final camera cost. Each component is purchased individually, so manufacturers are free to choose the best value for each part. Thus, the cost of the camera can be optimized for the level of performance delivered.

Shortcoming

- Longer development cycles: Components are integrated earlier in the development process than full modules. Therefore, the product development cycle of components is longer than that of modules. Components require additional development work in areas such as electronics and image calibration algorithms.

- The need for in-house capabilities: Integrating components into products requires specific expertise and resources, especially in electronics, mechanical engineering, and signal processing. Components are technically more complex than modules - which is why components are more adaptable.

The decision to develop a product based on components or modules depends largely on your new product development and business needs and goals. It's important to remember that modules are the right choice to speed up development. However, components offer more possibilities in adapting the system to the needs of the final product and controlling costs.

The above briefly introduces the difference between components and modules, if you want to buy infrared camera modules or components, please contact us.

As an infrared thermal imaging systems manufacturer with many years of experience, JAVOL has a wide range of applications. We enjoy a good reputation in the industry with high-quality products and a considerate service attitude. We have a professional production team and a strict quality inspection system, which can fully control the quality of our products. Our company designs develops and manufactures advanced imaging products and system solutions, which are widely used in machine vision, automatic driving, drone payloads, high-end manufacturing, medical diagnosis and other fields.

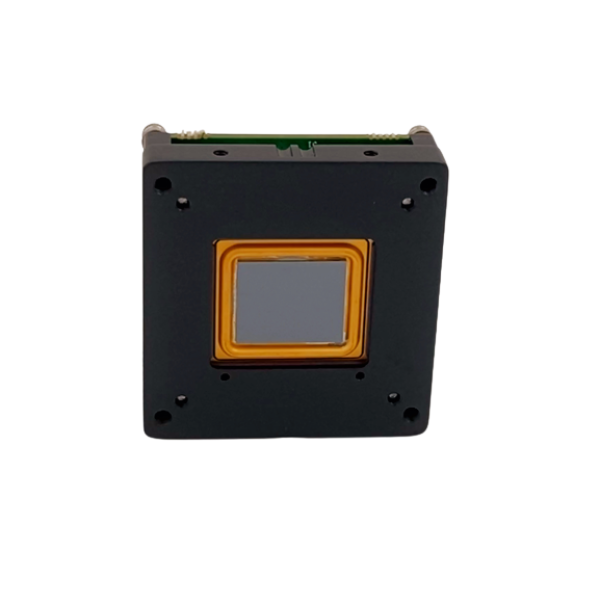

LWIR 640 Thermal imaging core is a uncooled focal plane infrared thermal imaging camera.

SWIR 640 thermal imaging camera adopts the latest advanced InGaAs sensor,which has many advantages.

Low-illumination camera can provide you excellent fog-penetration and low-illumination ability